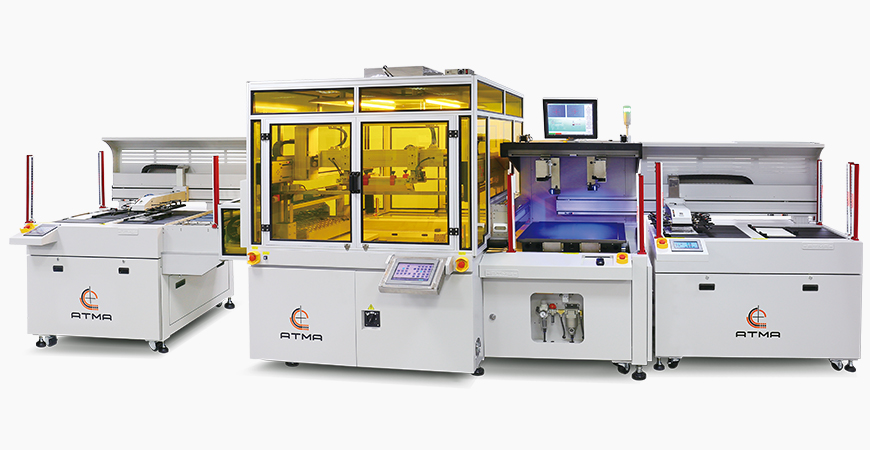

IoT Visual RegisteringThin Film Screen Printer (max sheet size 600x700 mm)

Standalone automation is configured with in /output structure and camera registration...

Read MoreCCD Registering Screen Printer, Thin Film Screen Printer

Suitable for high precision screen printing thin film display, pressure induction elements, FPC, etc

Character of this machine : high flatness of vacuum table, vacuum holes size can be made to match substrate thickness demandCCD camera auto registering, table is equipped with three axis servo motor to work with CCD function of offset compensation, the print head is driven by guide rail cylinder to make the equalized air pressure completely express onto printing pressureEnable to choose optional cleaning roller to pick up dust or particles quickly, anti-static bar to eliminate electrostatic on substrate to facilitate printing smoothlyEnclosure to keep printing chamber clean, throughout overall solution to increase high efficient printing production yield rate.

| Model | ATMATIC MF66/FI |

|---|---|

| Table Size | 750x750mm |

| Substrate Thickness | 0.05〜6.0mm |

| Max Printing Area | 500x500mm |

| Min Printing Area | 300x250mm |

| Productivity | 180P/H |

| Max Frame O/D Size | 1100x1100mm |

| Min Frame O/D Size | 900x900mm |

| Frame Height | 25〜45mm |

| Power Consumption | 5KW |

| Air Exhaustion | 76L/min |

| Machine Dimension | 6950x2020x2020mm |

| Machine Weight | 3410kg |

Suitable for precise screen printing capacity type touch panel, ITO conductive glass, ITO conductive film, blood sugar tester, EL panel, etc. Characteristic : high accuracy of vacuum table flatness, appropriate vacuum hole diameter can be made depending on substrate thickness need, CCD visual auto registering, three sets of servo motor are equipped for vacuum table, collocated with CCD camera displacement function, the printing head is driven by guide rail cylinder, onto equalizing air pressure can be presented completely on printingOptional cleaning roller can be selected to pick up dust or particles rapidly, anti-static to eliminate electrostatic on substrate for smooth printingEnclosure keeps printing section clean, overall collocation to raise yield rate of efficient printing massive production

Suitable for precise screen printing capacity type touch panel, ITO conductive glass, ITO conductive film, blood sugar tester, EL panel, etc. Characteristic : high accuracy of vacuum table flatness, appropriate vacuum hole diameter can be made depending on substrate thickness need, CCD visual auto registering, three sets of servo motor are equipped for vacuum table, collocated with CCD camera displacement function, the printing head is driven by guide rail cylinder, onto equalizing air pressure can be presented completely on printingOptional cleaning roller can be selected to pick up dust or particles rapidly, anti-static to eliminate electrostatic on substrate for smooth printingEnclosure keeps printing section clean, overall collocation to raise yield rate of efficient printing massive production

Standalone automation is configured with in /output structure and camera registration...

Read More

DD servo cylinder press with camera registration to attain the centered high precise printing...

Read More

Multi-function automatic Roll-to-Roll production line for all flexible rolled material,...

Read More