Screen Printing Peripherals

Support pre-printing and post-printing to present quality of screen printing image.

ATMA is specialized in making screen printing equipments for four decades and is committed to top quality, wide range of product line provides one-stop service to complete screen printing production. Custom-made order also can be accepted.

ATMA screen printing peripheral equipments and accessories is to support prepress, printing and post-printing to secure the printing image quality, which includes various items as mentioned below.

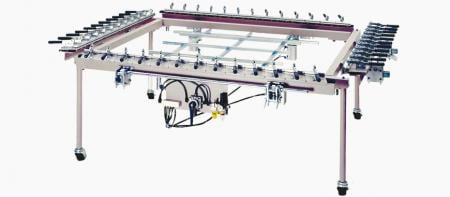

1. Mechanical Screen Fabric Stretching Machine is used to stretch the mesh fabric to reach the requested tension for making high precision screen.

2. Digital Emulsion Coating Machine is applied to coat the photosensitive emulsion evenly onto screen mesh for the printing image development. Optional double frame coating can be provided upon order request.

3. UV Exposure is necessary for making screen, the quality image can be developed onto the emulsion coated screen.

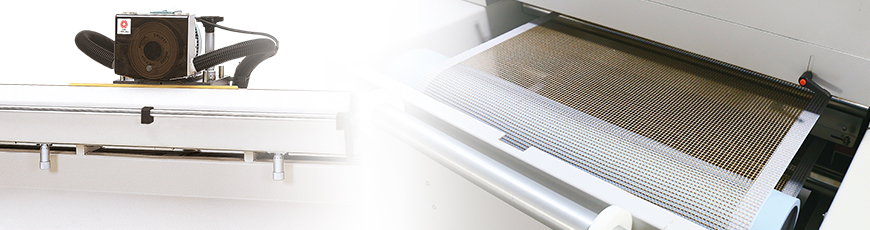

4. Stencil Dryer is used to dry the screen evenly and rapidly.

5. Manual Screen Printing Table is used for simple manual screen printing and handcraft graphic sampling.

6. Washing Booth is used for washing, developing, stripping process of screen making.

7. Ink Mixer is featured vibration shaking to combine ink and additive evenly within shortly.

8. Ink Stirring is suitable for uniform blending to merge ink and additive.

9. Fully Automatic Squeegee Sharpener is used to grind squeegee rubber edge sharpness and surface flatness.

10. Stencil Making Equipment includes the facilities to handle process of screen making which is including Screen Fabric Stretching Machine, Emulsion Coating Machine, UV Exposure, Wash Booth, Stencil Dryer

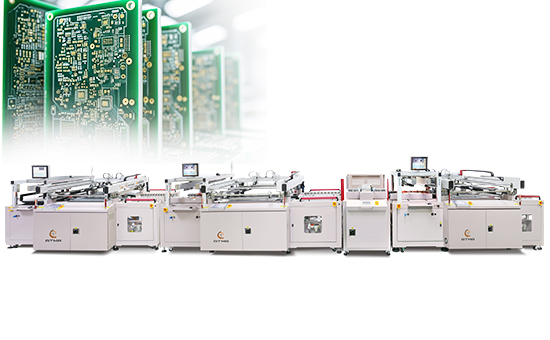

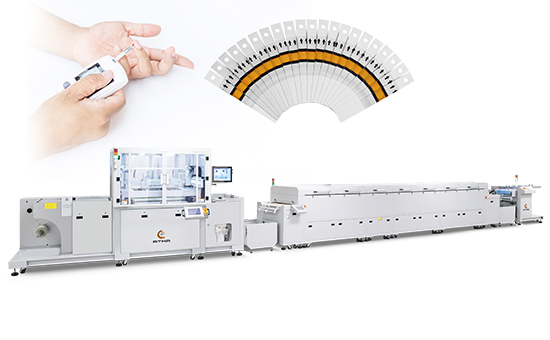

11. Post Printing Equipment includes Dryer and Unloading Stacker. ATMA Dryer is modular designed to provide UV, IR and hot air Dryer to adapt diverse ink character to secure quality of printing image.

12. Auxiliary Equipment include Screen Washer, Ink Mixer, Ink Stirring, Squeegee Sharpener

13. Accessories Consumable is as Screen Frame, Squeegee, Spatulas

Screen Printing Peripherals | ATMA

Browse our screen printer catalog to compare models by printing format, automation level, and line compatibility—then narrow to the best-fit options.

Since 1979, ATMA has focused on screen printing equipment, supporting buyers in selecting a screen printer and matching accessories like feeders and air dryers.

Tell us your material and output goals—ATMA will propose a screen printer setup and a clear shortlist to move forward.