Automotive Engine Gasket Screen Printer

Head Gasket Screen Printer, Cylinder Head Gasket Screen Printer, Engine Gasket Screen Printer

Suitable for multi-layer steel composite structure of irregular shape and twist the outer surface of the gasket coated with NBR glue screen printing processing, such can make the engine chamber in high horsepower, better sealing. For the process needs, special magnetic table plus positioning pin alignment can be made, magnetic holding metal gasket flattening to process screen printing. Applicable models handle printing area in range 400x600 ~ 800x800 mm.

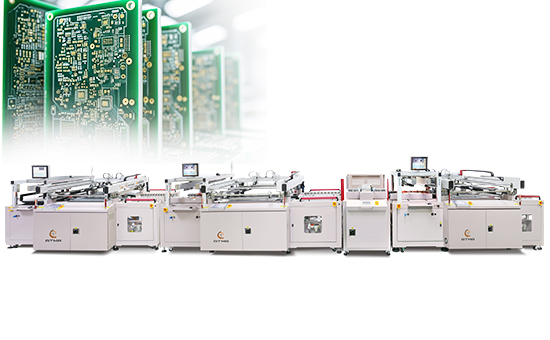

Applicable models

(1) Semi-automatic model :

AT-60PD

Digital Electric Flat Screen Printer

AT-80P

Electric Flat Screen Printer

(2) 3/4 Automatic model :

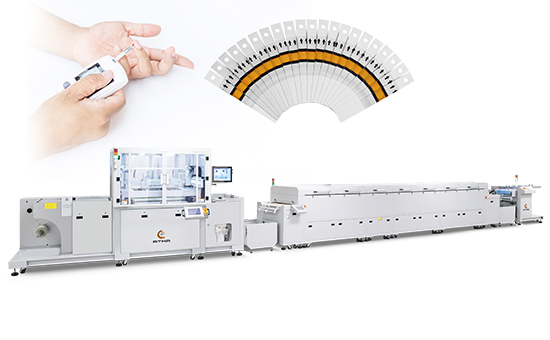

ATMAOE EG88/E

Engine Gasket Dedicated Screen Printer

Sliding magnetic table with pneumatic registration pins, magnetic holding metal gasket flattening to process screen printing.

Automotive Engine Gasket Screen Printer | ATMA

Browse our screen printer catalog to compare models by printing format, automation level, and line compatibility—then narrow to the best-fit options.

Since 1979, ATMA has focused on screen printing equipment, supporting buyers in selecting a screen printer and matching accessories like feeders and air dryers.

Tell us your material and output goals—ATMA will propose a screen printer setup and a clear shortlist to move forward.