Roll-to-Roll Screen Printing Line

Multi-function automatic Roll-to-Roll production line for all flexible rolled material,...

Read More

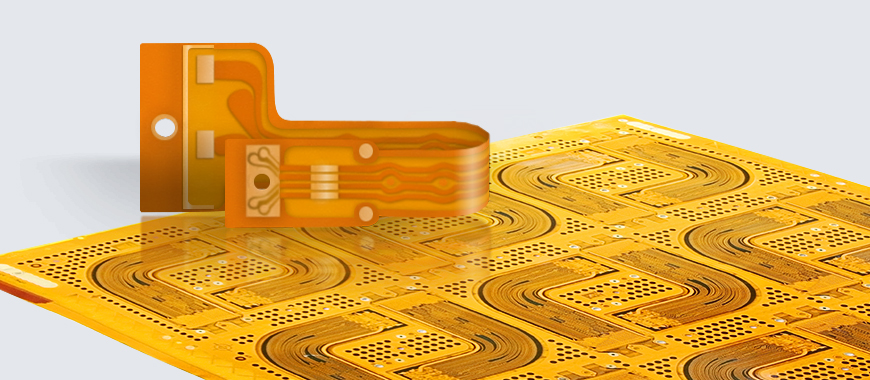

Flexible circuit board is abbreviated as FPC, the circuit layout is made on the flexible substrate by screen printing, as a transmission intermediary for the electronic product signal. Because of continual automated production, increasing wiring density, light weight, small size, reduce wiring error, flexibility and elastically to change shape and so characters, widely applied for consumable electronic products such as LCD screen for notebook, smart phone, tablet PC and hard disc storage device etc. By connecting FPC and motherboard, between LCD screen or various different components to attain signal transmission and foldable cover or rotating and so on function. After the electronic products went to the trend of light weight slim and short, they had a great motivation for the growth of FPC.

Three types of screen printer, semi-auto, twin table, fully automatic FPC roll-to-roll screen printing line.

Semi-auto Printing :

AT-60PD

(400x600mm) Digital Electric Flat Screen Printer

Twin Table Printing :

ATMAOE 56

(500x600mm) Opto-electronic High Precision Screen Printer

Fully Automatic Roll-to-Roll Screen Printing Line :

ATMALINE RR3250-C

(320x500mm) Fully Automatic FPC Roll-to-Roll Screen Printing Line

Suitable for precise screen printing capacity type touch panel, ITO conductive glass, ITO conductive film, blood sugar tester, EL panel, etc. Characteristic : high accuracy of vacuum table flatness, appropriate vacuum hole diameter can be made depending on substrate thickness need, CCD visual auto registering, three sets of servo motor are equipped for vacuum table, collocated with CCD camera displacement function, the printing head is driven by guide rail cylinder, onto equalizing air pressure can be presented completely on printingOptional cleaning roller can be selected to pick up dust or particles rapidly, anti-static to eliminate electrostatic on substrate for smooth printingEnclosure keeps printing section clean, overall collocation to raise yield rate of efficient printing massive production

Suitable for precise screen printing on Flexible Printed Circuits, ITO Conductive Film, Blood Sugar Tester, EL panel, etc Advantage of this machine : auto feeding→CCD registering→printing→collecting High flatness vacuum table top, vacuum holes size can be made to match substrate thickness, CCD camera detects auto registering, three axis servo motors are equipped for table to collocate CCD to make compensation of displacement function, printing head adopts guide rail cylinder, constant equalized air pressure can be rendered onto printing, thru overall collocation scheme, high efficiency raises yield rate of printing capacity production.

Suitable for precise screen printing on Flexible Printed Circuit (FPC), capacity type touch panel, ITO conductive glass, ITO conductive film, blood sugar tester, EL panel, etc. Characteristic : high accuracy of vacuum table flatness, appropriate vacuum hole diameter can be made depending on substrate thickness, CCD visual system collaborates with three servo motors for auto substrate registering, printing head equips guide rail cylinders for equalized air pressure to be presented completely on printing pressureOptional cleaning roller can pick up dust or particles rapidly; anti-static bar can eliminate electrostatic on substrate for smooth printing; enclosure keeps printing section cleanThrough overall collocation to raise yield rate of efficient printing in massive production.

Suitable for high precision screen printing thin film display, pressure induction elements, FPC, etcCharacter of this machine : high flatness of vacuum table, vacuum holes size can be made to match substrate thickness demandCCD camera auto registering, table is equipped with three axis servo motor to work with CCD function of offset compensation, the print head is driven by guide rail cylinder to make the equalized air pressure completely express onto printing pressureEnable to choose optional cleaning roller to pick up dust or particles quickly, anti-static bar to eliminate electrostatic on substrate to facilitate printing smoothlyEnclosure to keep printing chamber clean, throughout overall solution to increase high efficient printing production yield rate.

Multi-function automatic Roll-to-Roll production line for all flexible rolled material,...

Read More

Breakthrough conventional process mode, three times printing with three times drying,...

Read More

Screen printing speed attains highest 4000 cycles per hour within industry, under high...

Read More