Printed Circuits Legend Screen Printer/ Legend Lnkjet

Automatic PCB Legend Screen Printer, Fully Automatic PCB Double Sided Legend Screen Printer, PCB Legend Inkjet Printer

Three types of screen printer, semi-automatic, twin table, fully automatic printing line, (delivery to dryer, or drying rack, etc. after printing accomplishment), directly printing legend, plug-via hole, solder mask, conductive ink (silver or carbon) electrode / circuits etc. onto rigid / flexible panel.

Semi-automatic printing :

AT-70PD

Digital Electric Flat Screen Printer

AT-80P

Electric Flat Screen Printer

AT-80P/B

Electric Flat Screen Printer with Belt Take-off

AT-120P

P Electric Flat Screen Printer

ATMECH 57

Clamshell Flat Screen Printer

Automatic printing :

ATMAOE PC66

Fully Automatic CCD Registering PCB Legend Screen Printer

ATMAOE PC68

Fully Automatic CCD Registering PCB Legend Screen Printer

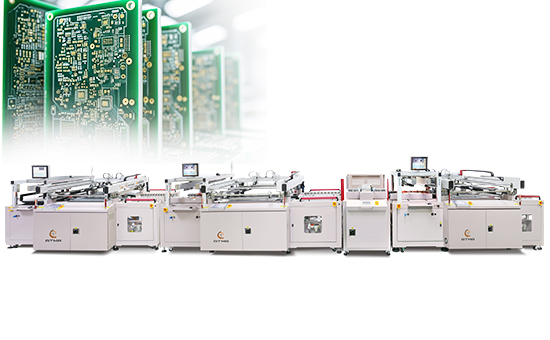

Fully Automatic Printing Line :

Three machine in one, connecting cleaning machine with drying→plug-via printing→C side solder mask printing→automatic turn over→S side solder mask printing→hang up drying→collection

ATMALINE PC68-PL

Fullt Automatic PCB Double Sided Legend Screen Printinng Line

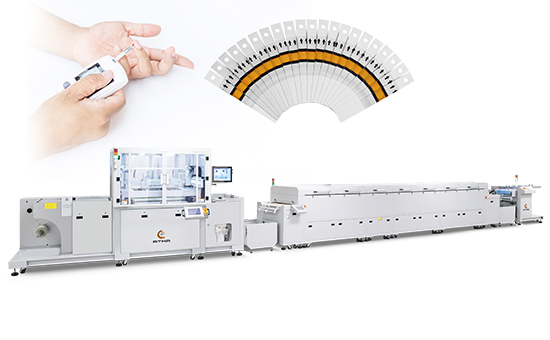

Digital Inkjet, Inkjet Printer, Legend Inkjet Printing Machine :

ATMA-IJ 2529

Digital inkjet is dedicated to print PCB legend, and IC substrate marks

Fully Automatic Printed Circuits Double Sided Legend Screen Printing Line

ATMALINE PC68-PL

Special use for multi-layer PCB double sided legend automatic screen printing lineStrategic allied with customer demand for R&D, thru customer enquiry to obtain demand to study feasible production and layout...

DetailsFully Automatic CCD Registering PCB Screen Printer (max printing area 600x600 mm)

ATMAOE PC66

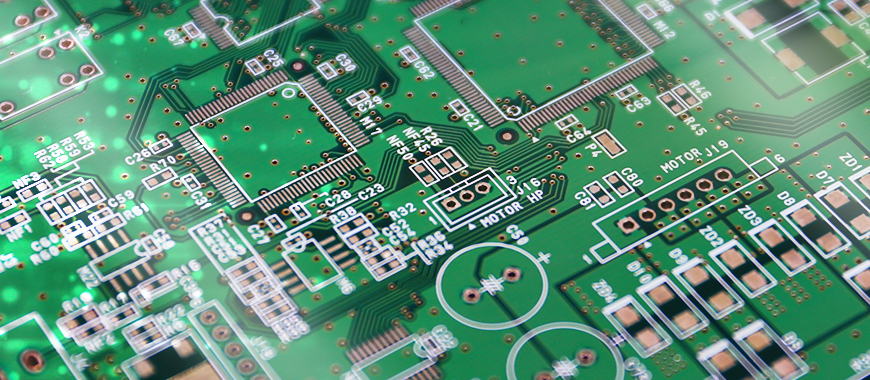

Specialized in fully automatic screen printing legend on rigid PCBMain purpose for legend printing is to indicate electronic component symbol to show its mounting position PCB is made of 20-30 processing...

DetailsFully Automatic CCD Registering PCB Screen Printer (max printing area 600x800 mm)

ATMAOE PC68

Dedicated to automatic screen printing legend on rigid PCB Primary purpose of printing legend on PCB is to mark symbols of components to indicate mounting position.PCB is made thru 20~30 steps of processing,...

DetailsPrinted Circuits Legend Screen Printer/ Legend Lnkjet | ATMA

Browse our screen printer catalog to compare models by printing format, automation level, and line compatibility—then narrow to the best-fit options.

Since 1979, ATMA has focused on screen printing equipment, supporting buyers in selecting a screen printer and matching accessories like feeders and air dryers.

Tell us your material and output goals—ATMA will propose a screen printer setup and a clear shortlist to move forward.