PCB Screen Printing Machine

Screen Printing Machine is used to print solder mask, legend, wet-film plug-via process to make PCB

Silk-screen printing is crucial processing of PCB fabrication such as solder mask, legend or marks, wet-film plug-via processing. ATMA is dedicated to providing screen printing solutions for various types of rigid or flexible PCBs like single layer or multi-layer PCBs, and single-sided or double-sided PCBs

Silkscreen Printing of PCBs solution applied rigid and flexible PCB printing approaches and processing

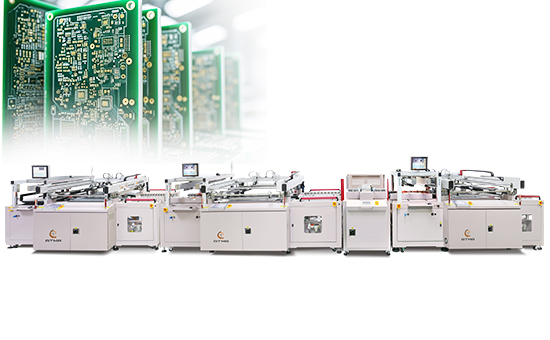

ATMA fully automatic PCB screen printing line is dedicated to handling rigid PCB with thickness 0.5 ~ 4.0 mm for printing plug-via, solder mask, and legend process. The automatic printing line is a modular design and work station can be selected according to customer processing requirements and layout footprint limitations, the line is connected with upstream processing for image exposure or etching and downstream drying inline processing to attain massive production to save labor and lower production cost. Moreover, ATMA automatic Roll-to-Roll screen printing is used to handling flexible PCB printing solder mask and legends for high batch productivity. Visual system is equipped to detect fiducial targets on screen and substrate at the same time for precise registration to adapt high speed printing with high yield rate. Also, the equalized pressure and adjustable mechanical device for squeegee / flood coater attains printing uniform ink layer and fineline. ATMA screen-printer portfolio includes semi-automatic, standalone automatic machine, and fully automatic printing line which can be incorporated into inline production to save labor with digitized management.

PCB Legend Text Printing

Legend or mark can be printed onto single-sided or double-sided PCB and single or multi-layer PCB. Except for the elements of the screen, ink, squeegee, etc. influencing printing quality, the stability and functionality of the machine are also important to collocate with screen, ink viscosity, and squeegee to present overall quality printing. ATMA screen-printer provides versatile features with digitalized control of the printing parameters to support the unskilled operator to handle clear and delicate fine line printing at narrow space in between circuits or patterns on PCB.

Solder Mask Printing is applied to PCBs

Liquid photo imageable solder resist ink is usually applied to the copper traces of a printed circuit board (PCB) for protection against oxidation and to prevent solder bridges from forming between closely spaced solder pads. ATMA screen printing machine is equipped with double squeegee and double peel-off with digital setting the recipe parameters, adding features of the adjustable squeegee skew angle and pressing pressure can control printing uniform ink layer thickness to present good outlook appearance on PCB.

Plug via Process for Printed Circuit Board Manufacturing

Plug-via printing is used to make an electrical connective between the layers of a multi-layer PCB. Connecting multiple layers of a board makes it possible to reduce the size of the PCB, as layers can be stacked. ATMA screen printer is specially designed for the robust structure to support high-pressure printing plug-via with high ratio aspect for through-hole via and buried via process, plug-via fills up holes completely without air bubble blowout upon drying. ATMA also has a special screen printer with a vacuum chamber to handle blinds via a micro holes process to satisfy PCB fabrication.

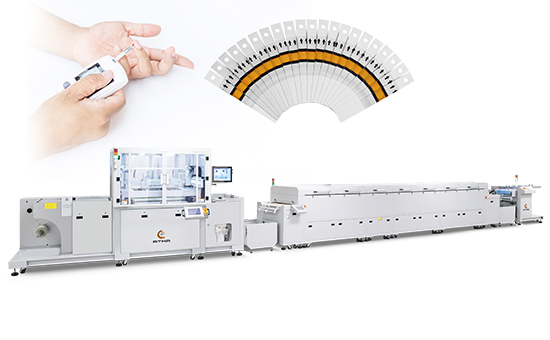

Flexible PCB Printing:

Flexible circuits are typically manufactured using a polyimide (Kapton) material and one to multiple layers of copper. The copper foil was processed by etching treatment to emerge fine line circuits, legend (or marks), and solder mask is printed afterward. ATMA provides two solutions for printing solder mask, legend (or marks), silver and carbon paste onto flexible PCB like flatbed and roll-to-roll screen printing as stated below :

1.ATMA flatbed screen printer is suitable for printing sheet by sheet to continue processing after upstream image exposure and etching process. Since ATMA flatbed screen printer has the vacuum tabletop which is machined to achieve high accuracy of flatness and is equipped with the adjustable features for printing to attain even ink layer thickness, and the delicate fine line of legend (or marks) is printed on top of solder mask as well. The optional unloading device can be added to upgrade as 3/4 automatic to save labor increasing production efficiency.

2.ATMA roll-to-roll screen printer is suitable for high productivity printing the coiled flexible foils to continue processing after upstream image exposure and etching process. This screen printer is equipped with a high-resolution CCD camera to achieve accuracy registering and is incorporated with a drying section to meet high production efficiency.

PCB Screen Printing Machine | ATMA

Browse our screen printer catalog to compare models by printing format, automation level, and line compatibility—then narrow to the best-fit options.

Since 1979, ATMA has focused on screen printing equipment, supporting buyers in selecting a screen printer and matching accessories like feeders and air dryers.

Tell us your material and output goals—ATMA will propose a screen printer setup and a clear shortlist to move forward.