Core Competence

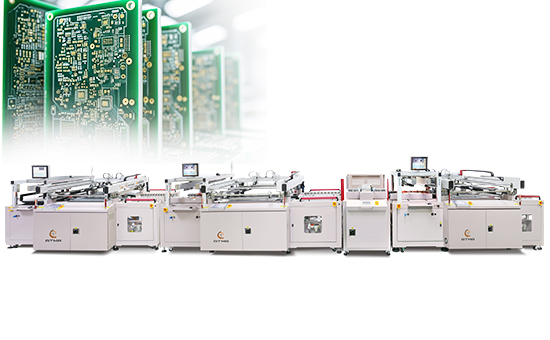

Highest Productivity

Components are assembled by batch quantity in streamline, machine is assembled by production line, assembly efficiency is enhanced to meet customer urgent need and batch order to ensure delivery on time, annual production quantity exceeded 4000 sets, it is ranked top one within industry.

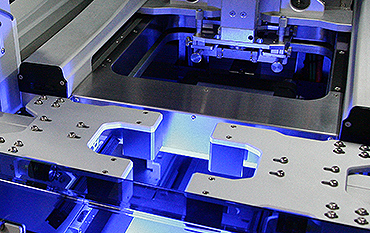

Effective Control Quality of Spare Parts

Use the state-of-the-art CNC tooling machine, attached with four-axis and five-axis tooling to positioning for multi-faceted processing, raise processing quality and delivery control

Modularized and Standardized

RD design adopts massive quantity of Aluminum extrusion profile and standardized sub-components application module to raise product development efficiency and cost.

Strength of R&D

R&D team occupies 25% manpower of company, strongest R&D team top one bespoke capability within industry, possessed highest number of 15 patent leading screen printing industry

Plenty Experience with Integration of Electro-mechanical

Used by CCD visual technology and registration table control to make µ class precise registering to raise customer product quality.

Core Competence | Work with a Screen Printing Equipment Manufacturer

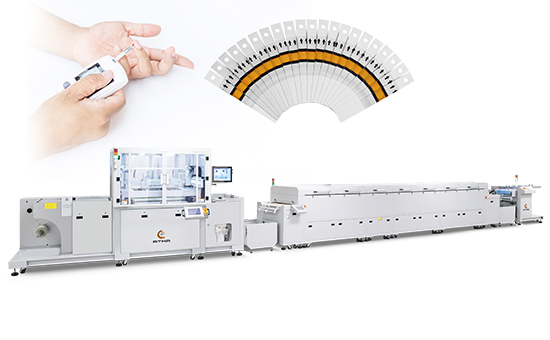

Meet ATMA—an established screen printing equipment manufacturer—so you can evaluate suppliers with clear product scope and support expectations.

Since 1979, ATMA has manufactured screen printers and related modules, including feeders, air dryers, coating machines, and ink mixers for production lines.

Share your application and project goals—ATMA will suggest suitable screen printing equipment options and the next steps to move forward.