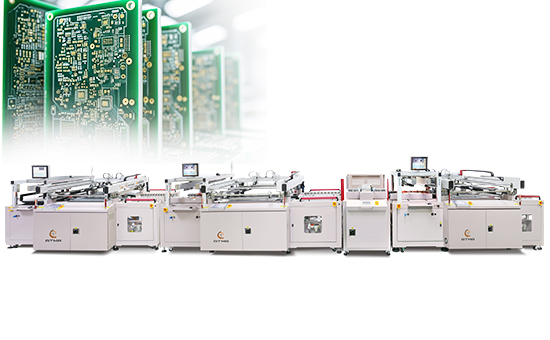

Industrial Screen Printing Machine

ATMA screen printing solution is part of making industrial products function or outlook decoration.

ATMA provides wide range of industrial printing machine as flat or curved screen printer for decorative printing or functional coating on rigid or flexible substrates like plastic, metal, mylar, glass, etc. ATMA professionally supports all projects for custom-made from concept to design, manufacturing and turnkey installation.

Industrial screen printing is a part of overall production process and can be split into decorative and functional screen printing in according to product application. Decorative printing can make the product outlook appearance luxury or fancy. Functional printing brings the functionality to the products, Both enable to increase the product value-added.

Flat screen printing can be applied for diverse industrial products as stated below :

Screen printing automotive Dashboard

Strong control screen printing all parameters of opacity, texture, transfer, light and color is required. ATMA silk-screen printing machine is configured with the equalizer to control squeegee constant air pressure printing uniform ink layer to attain image thru backlight even transparently. Also, it is featured with mechanical pin alignment or visual system registration in according to customer production need to achieve high repeatability registration accuracy to present sharp and fine line image.

Screen printing automotive Gasket

Screen printing machine is applied to coat grommet with molybdenum disulfide on the surface to avoid scratch, rubber coating onto surface achieves better sealing performance to resist engine high pressure and prevent leakage. ATMA silk-screen printer has featured with the adjustable squeegee / flood coater to attain skew angle printing and prevent the substrate’s sharp edge and corners to tear-off mesh. Also, the equalizing air pressure controls the squeegee printing uniform ink layer for excellent sealing.

Screen printing nameplate and cards

Screen printing is a part of making nameplate to provide explicit information or sign as user identification or product parameters, fine line graphical and literal printing can be done by the precise alignment and stable printing speed with the equalized pressure. ATMA silk-screen printer is suitable for flat nameplate and Cards decorative colored printing, it is configured with air locking frame holder with micro-adjustment for quick setup to exchange the screen and precise alignment for multi-color printing.

Screen printing membrane switch

ATMA provides screen printing equipment to handle crucial processing of making membrane switch, which is used as a switch on circuit boards. ATMA screen printing machine is used for massive production printing the graphics or pictogram as well as conductive ink for the contacts or circuits onto membrane switch. ATMA screen printers facilitate quick setup, easy operating to exchange screen for multi-color or multi-layer functional ink printing and high productivity.

Screen printing stereo casting or cubic housing

ATMA special design screen printer to have the slotted table with clamp plate assembly, which enables to get mounted the fixture to fix the cubic object in height 300 mm or below for printing. The slotted table can be adjusted by hand wheel with position indicator in according to cubic object height to accommodate different height of cubic objects. Handy operation facilitates quick manual loading and unloading. Custom-made is accepted for the fixture to adapt the specified cubic object.

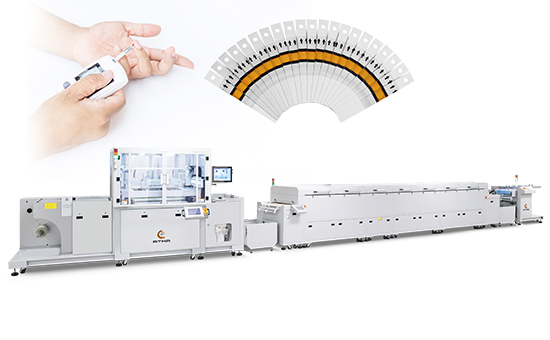

Screen printing transfer paper and decal

ATMA product line includes semi-auto and 3/4 automatic various models of flatbed screen printing to meet demand of diverse small production or massive batch production. ATMA flatbed screen printer is dedicated to print graphical multi-color for decorative and garment industry. High precise assembly is adopted for dynamical structure to attain stable movement and precise positioning. Handy adjustable structure is designed for fast setup and alignment. Additional, digital control is preset all recipe parameters, the inexperienced operator can handle quality printing. Moreover, ATMA provides fully automatic cylinder press for massive production with 4000 pcs per hour. This model is designed originally by the renowned German brand SPS, it was incorporated by ATMA and is improved market strength to meet diverse production.

Screen printing stationery, souvenir, gift, toys, shoe pad, ceramic tile

Various industrial products with small printing area which can be printed by ATMA mini flatbed screen printer to increase product value-added. Handy operation plug-and-play attains quick setup to save labor and time to fulfill diverse small amount production. Low cost of equipment may get rewarded from investment within shortly.

Curved printing by ATMA screen printer

ATMA solution of the curved printing is applied for various cylindrical, conical or oval shaped objects, such as mug, bottle, tube, pail, cans, cosmetic container, etc. ATMA curved screen printing machine is designed for seamless circumference printing. Automatic registration device is equipped to work along with the fixture for multi-color printing. Fixture is designed in according to the specified cylindrical (or curved) object. Advantage of ATMA curved screen printer is flexibility to adapt small volume diverse production, quick setup and user friendly.

Industrial Screen Printing Machine | ATMA

Browse our screen printer catalog to compare models by printing format, automation level, and line compatibility—then narrow to the best-fit options.

Since 1979, ATMA has focused on screen printing equipment, supporting buyers in selecting a screen printer and matching accessories like feeders and air dryers.

Tell us your material and output goals—ATMA will propose a screen printer setup and a clear shortlist to move forward.