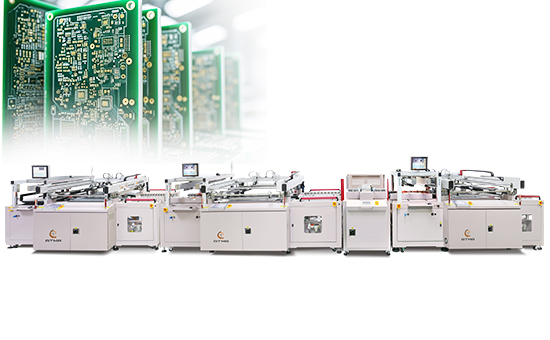

Fully Automatic PCB Plug-via Solder Mask Screen Printing Line

ATMALINE PC68-SP

Fully Automatic PCB Screen Printer, Fully Automatic Plug-via Solder Mask Screen Printer, Plug-via Solder Mask Screen Printer

Specialized in automatic multi-layer PCB plug-via solder mask screen printing line processR&D strategic alliance with customer thru enquiry, once understanding demand to issue production proposal and layout planning, all feature function is settled, technical R&D will be carried outThis machine is consisted of automatic plug-via + buffer stacker + C side plug-via screen printer + buffer stacker + automatic positioning turn over + S side solder mask screen printer to attain fully automatic production efficiencyOne way is to reduce manpower and another way to save energy carbon reduction (original process 3-times printing with 3-times drying reduce to 3-times printing with 1-times drying.)

Among crucial points is to make fixture for air conduction while plug-via process + automatic positioning turn over CCD camera detection, fixture for C/S side can be overcome, digital control driven replaces three-point micro adjustment function to assure smooth workflow, this is also unique invention of automatic plug-via solder mask inline massive production machine all over the world

Features

- Visual Registration : 2 CCD cameras detect registration mark or hole on substrate rapidly, mathematically calculate position off-set amount providing to control system, X/Y servo transmission system drives registration table immediately to precise position

- Laser Point : CCD camera module is locked / unlocked by pneumatic control switch, fast displacement and manual fine adjusting front back / right left position, collocated with laser point projection for quick moving to target position.

- Digital Control Screen Micro Adjustment : replace manual three-point micro adjustment, which is unable to adjust precisely obtaining the requested position, digitalized control compensation attains quick precise efficiency.

- Buffer Stacker : when B side screen printer stops for screen cleaning, A side incoming after printing, temporary stack into buffer stacked to avoid influence production efficiency

- Automatic Positioning Turn Over : accomplished A side legend printing and transported to turn over, servo drive CCD to detect registration mark on B side for legend printing

- Clipper Flattening : substrate is deformed after various processing, clipper pulls to extend bilateral sides flattening while turn over to facilitate CCD registering, especially for thin film outstanding efficiency

Specification

| Model | ATMALINE_PC68-SP |

|---|---|

| Substrate Thickness | 0.8〜3.0mm |

| Max Printing Area | 730x730mm(28.5”x28.5”) |

| Min Printing Area | 360x360mm(14”x14”) |

| Productivity | 300〜360 pcs/min |

| Power Source | 3∮,380V,50/60Hz |

| Max Frame O/D Size | 1200X1200mm |

| Min Frame O/D Size | 900x900mm |

| Vacuum Hole Diameter | ϕ2mm |

| Integrated CCD Accuracy | 0.02mm |

| Buffer Storage | 25 pcs |

| Entire Line Length | 90x1886x2200mm |

| Entire Line Weight | 8,590kgs |

Other models in the same series but different sizes:

ATMAOE PC68 (max printing area 760x760mm)ATMAOE PC68-PV (max printing area 760x760mm)

ATMALINE PC68-SM (max printing area 760x760mm)

- Related Products

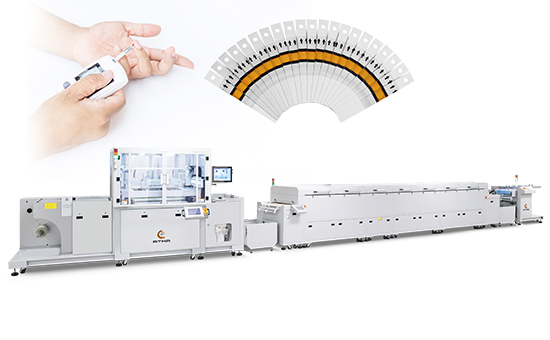

Fully Automatic CCD Registering PCB Screen Printer (max printing area 600x800 mm)

ATMAOE PC68

Dedicated to automatic screen printing legend on rigid PCB Primary purpose of printing legend on PCB is to mark symbols of components to indicate mounting position.PCB is made thru 20~30 steps of processing,...

Details

Fully Automatic PCB Plug-via Solder Mask Screen Printing Line | ATMA

Use our Fully Automatic PCB Plug-via Solder Mask Screen Printing Line to compare machine types by application—sheet, cylinder press, or roll-to-roll—so you can shortlist the right format for your production.

ATMA has manufactured screen printing equipment since 1979, and we can help you align the screen printer with feeders, dryers, coaters, and ink mixing modules.

Share your substrate, print size, and throughput target—ATMA will recommend a screen printer configuration and the next steps for evaluation.