Electric Flat Screen Printer (regular size 600x800 mm)

AT-80P

Flat Screen Printer, Flat Silk Screen Printer, Two-post Type Screen Printer, Electric Type Screen Printer, Vertical Up Down Silk Screen Printer

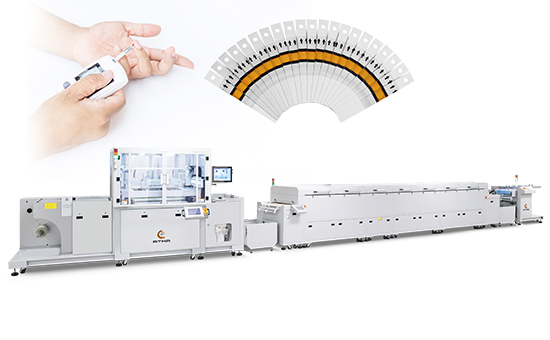

Electric flat screen printer is suitable for printing industrial products such as Membrane Switch, Flexible Printed Circuits (FPC), Nameplate, Electro-luminescent, etc.

Aluminum alloyed extruded formation structure, high strength and light weight to raise durability and accuracy to support heavy dutyMotor driven screen vertical up down rapidly, equipped with safety buffer cylinder (patented)When the screen descends at printing level, if E-stop switch is triggered, all stroke of machine operating is stopped automatically, safety auxiliary cylinder is automatically inflated against the weight of the print head carriage and frame holder assembly, slight manually push up the screen ascent, comprehensive protecting the operator safetyDuring screen traveling, when the screen is descending and is not reached at the printing level, if E-stop is triggered, screen is moved up slowly to origin positionPrinting stroke is driven by servo motor, enhance speed range and stable linear speed motion

HMI displays Chinese / English language, digitalized control to select or setting versatile printing cycle modes rapidlyDepending on substrates different need, fast and convenient to attain printing efficiency and fulfill various printing needSafety protective loop, if malfunction or erroneous setting or operating, machine is stopped immediately and HMI displays error message, attached with restoration iconTwist E-stop switch to restore origin to protect operator safety

Features

- Innovative Design : motorized driven screen vertical up down design, quick and silent stable motion, equipped with safety auxiliary buffer cylinder (patented), comprehensive protecting operator safety.

- Aluminum Extrusion Profile : Aluminum alloyed extrusion formation structure, high strength with light weight, raise durability and accuracy to support heavy duty.

- Convenient Adjustment : screen frame holder is designed by active cantilever arm, light weight and strong structure, easy and fast adjusting movement.

- Digitalized Control : PLC control, versatile function, easy and quick operation.

- Quick Operation : HMI displays Chinese / English language, digitalized control achieves quick selection and setting.

- Error Display : LCD display malfunction and error message to guide explicitly trouble shooting.

- Comprehensive Protection : equipped with E-stop switch, safety bar, safety press plate and auto restoration stroke start point design, protect operator to reduce defective rate.

- Option : pneumatic registration pin / pop-up pin, dripless squeegee, light barrier protection.

Specification

| Model | AT-80P |

|---|---|

| Substrate thickness | 0〜25 mm |

| Productivity | 570 P/H |

| Max printing area | 600 x 800 mm |

| Max frame O/D size | 900 x 1100 mm |

| Table size | 700 x 900 mm |

| Power consumption | 2.6 KW |

| Air exhaustion | 3.0 L/cyle |

| Machine weight | 685 kg |

| Machine dimension | 1500 x 1300 x 1700 mm |

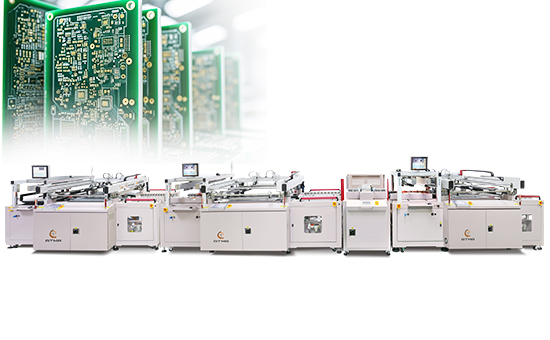

Other models in the same series but different sizes:

AT-80P/B (max printing area 600x650mm)AT-80PP/G (max printing area 600x740mm)

AT-80P/SV (max printing area 600x800mm)

AT-120P (max printing area 700x1200mm)

AT-160P (max printing area 700x1600mm)

- Related Products

Electric Flat Screen Printer (regular size 600x800 mm) | ATMA

Use our Electric Flat Screen Printer (regular size 600x800 mm) to compare machine types by application—sheet, cylinder press, or roll-to-roll—so you can shortlist the right format for your production.

ATMA has manufactured screen printing equipment since 1979, and we can help you align the screen printer with feeders, dryers, coaters, and ink mixing modules.

Share your substrate, print size, and throughput target—ATMA will recommend a screen printer configuration and the next steps for evaluation.