Automotive Engine Gasket Special Screen Printer

ATMAOE EG88/E

Engine Gasket Screen Printer

Specialized in precise screen printing on gasket for automotive or truck engine.

Characteristic : high flatness magnetic table, completely fixing the gasket on table while printing, registration pins are added on table top, printing head is driven by guide rail cylinder to make the equalized air pressure completely to be presented onto printing pressure.

Features

- Four-post Air Locking : equipped with unique four-post air locking function (activated while printing), assure printing stroke and table top parallel leveling to raise printing accuracy.

- Magnetic Suction : suitable for fixing different size and pattern of gasket on table for printing.

- Printing Uniform Ink Layer : squeegee / flood coater is driven by guide rail cylinder to raise accuracy of linear motion, leading accuracy, smooth to make equalized printing pressure resented onto substrate, assure printing ink layer even and consistency.

- Servo Motor Direct Drive : none malfunction, solid printing torque, full digital control attains stable speed motion.

- Equalized Control : squeegee / flood coater digital equalizer system control, enable to preset air pressure (3~ 62 kgf) on HMI

- Safety Protection : interlocking error diagnosis, error indication, mono key auto safety restoration loop, protective light barrier, E-stop switch, colored warning lamp and so on, comprehensive protection.

Specification

| Model | ATMAOE EG88/E |

|---|---|

| Table size | 850x950mm |

| Substrate thickness | 0.25〜0.35mm |

| Max printing area | 800x800mm |

| Min printing area | 300x400mm |

| Productivity | 540 P/H |

| Max frame O/D size | 1300x1300mm |

| Min frame O/D size | 1050x1050mm |

| Frame height | 25〜40mm |

| Power consumption | 4.6KW |

| Air exhaustion | 30L/min |

| Machine dimension | 3480x1930x1935mm |

| Machine weight | 1980kg |

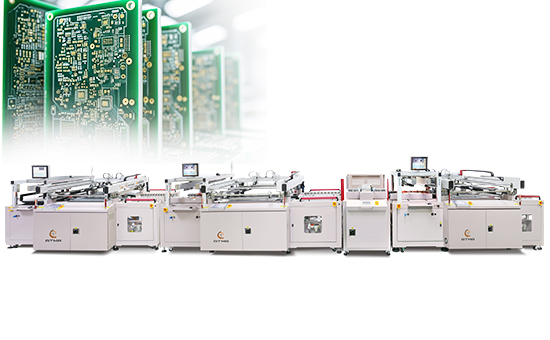

Other models in the same series but different sizes:

ATMAOE MF66 (max printing area 610x610mm)ATMAOE MF88 (max printing area 800x800mm)

- Related Products

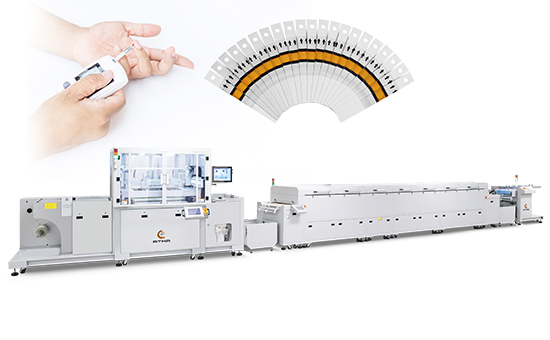

Fully Automatic CCD Registering Screen Printer (max printing area 600x600 mm)

ATMAOE MF66

Suitable for precise screen printing capacity type touch panel, ITO conductive glass, ITO conductive film, blood sugar tester, EL panel, etc. Characteristic : high accuracy of vacuum table flatness, appropriate...

DetailsFully Automatic CCD Registering Screen Printer (max printing area 800x800 mm)

ATMAOE MF88

Suitable for precise screen printing capacity type touch panel, ITO conductive glass, ITO conductive film, blood sugar tester, EL panel, etc. Characteristic : high accuracy of vacuum table flatness, appropriate...

Details

Automotive Engine Gasket Special Screen Printer | ATMA

Use our Automotive Engine Gasket Special Screen Printer to compare machine types by application—sheet, cylinder press, or roll-to-roll—so you can shortlist the right format for your production.

ATMA has manufactured screen printing equipment since 1979, and we can help you align the screen printer with feeders, dryers, coaters, and ink mixing modules.

Share your substrate, print size, and throughput target—ATMA will recommend a screen printer configuration and the next steps for evaluation.