Roll-to-Roll Screen Printing Line

Multi-function automatic Roll-to-Roll production line for all flexible rolled material,...

Read More

ATMA is specialized in making screen printing equipments for four decades and is committed to top quality, wide range of product line provides one-stop service to complete screen printing production. Custom-made order also can be accepted.

ATMA screen printing peripheral equipments and accessories is to support prepress, printing and post-printing to secure the printing image quality, which includes various items as mentioned below.

1. Mechanical Screen Fabric Stretching Machine is used to stretch the mesh fabric to reach the requested tension for making high precision screen.

2. Digital Emulsion Coating Machine is applied to coat the photosensitive emulsion evenly onto screen mesh for the printing image development. Optional double frame coating can be provided upon order request.

3. UV Exposure is necessary for making screen, the quality image can be developed onto the emulsion coated screen.

4. Stencil Dryer is used to dry the screen evenly and rapidly.

5. Manual Screen Printing Table is used for simple manual screen printing and handcraft graphic sampling.

6. Washing Booth is used for washing, developing, stripping process of screen making.

7. Ink Mixer is featured vibration shaking to combine ink and additive evenly within shortly.

8. Ink Stirring is suitable for uniform blending to merge ink and additive.

9. Fully Automatic Squeegee Sharpener is used to grind squeegee rubber edge sharpness and surface flatness.

10. Stencil Making Equipment includes the facilities to handle process of screen making which is including Screen Fabric Stretching Machine, Emulsion Coating Machine, UV Exposure, Wash Booth, Stencil Dryer

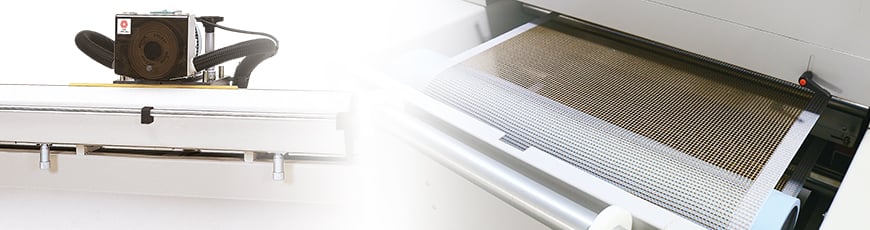

11. Post Printing Equipment includes Dryer and Unloading Stacker. ATMA Dryer is modular designed to provide UV, IR and hot air Dryer to adapt diverse ink character to secure quality of printing image.

12. Auxiliary Equipment include Screen Washer, Ink Mixer, Ink Stirring, Squeegee Sharpener

13. Accessories Consumable is as Screen Frame, Squeegee, Spatulas

Specialized in high precision coating of photosensitive emulsion onto screen mesh.

For sharpening squeegee blade on holder in order to obtain flat straight and sharp edges, so to assure excellent printing quality. Max. grinding stroke 1000 / 1500 mm.

For stretching screen fabric to make a screen printing stencil, robust structure fulfills requirement on high tension / bias-angle stretching.

For automatic mixing ink and additives, replacing manual operation.

For exposure-transferring artwork image on positive film to photosensitive emulsion layer coated on screen.

For rapid drying screen stencil(s). Fast heat-up, hot air stably circulated, temperature averagely spread, stencil(s) dried evenly. Stainless steel placement racks, horizontal or vertical type for choice.

Multi-function automatic Roll-to-Roll production line for all flexible rolled material,...

Read More

Breakthrough conventional process mode, three times printing with three times drying,...

Read More

Screen printing speed attains highest 4000 cycles per hour within industry, under high...

Read More