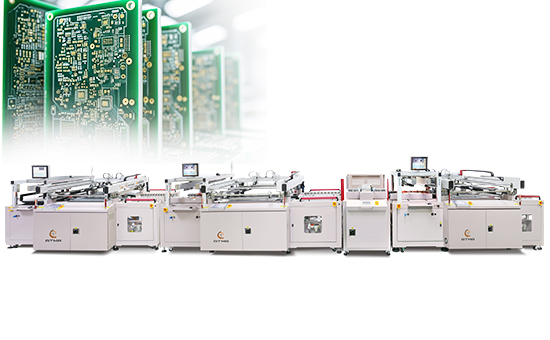

Automotive Touch Panel Screen Printing Machine

Automotive Touch Panel Screen Printer, Automotive Touch Display Screen Printer

Specialized in printing high value-added automotive glass, enable to match customer product character to layout inlet and outlet and collocate with up / downstream production to connect with automatic printing line.

In responding to the trend of intelligent and internet vehicle, automotive display panel shows information more and more enrichment, including : video / audio entertainment, instant navigation, traffic status information, auxiliary driving and so on. Thus, it is necessary to increase various types of display panel to response interactive of HMI.

Applicable models

ATMAOE MF66

(max printing area 610x610mm)

ATMAOE MF88

(max printing area 800x800mm)

Fully Automatic CCD Registering Screen Printer (max printing area 600x600 mm)

ATMAOE MF66

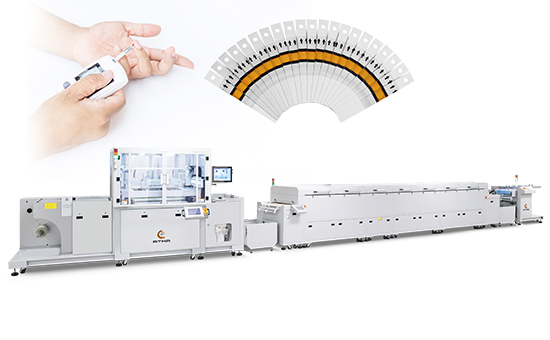

Suitable for precise screen printing capacity type touch panel, ITO conductive glass, ITO conductive film, blood sugar tester, EL panel, etc. Characteristic : high accuracy of vacuum table flatness, appropriate...

DetailsFully Automatic CCD Registering Screen Printer (max printing area 800x800 mm)

ATMAOE MF88

Suitable for precise screen printing capacity type touch panel, ITO conductive glass, ITO conductive film, blood sugar tester, EL panel, etc. Characteristic : high accuracy of vacuum table flatness, appropriate...

DetailsAutomotive Touch Panel Screen Printing Machine | ATMA

Browse our screen printer catalog to compare models by printing format, automation level, and line compatibility—then narrow to the best-fit options.

Since 1979, ATMA has focused on screen printing equipment, supporting buyers in selecting a screen printer and matching accessories like feeders and air dryers.

Tell us your material and output goals—ATMA will propose a screen printer setup and a clear shortlist to move forward.