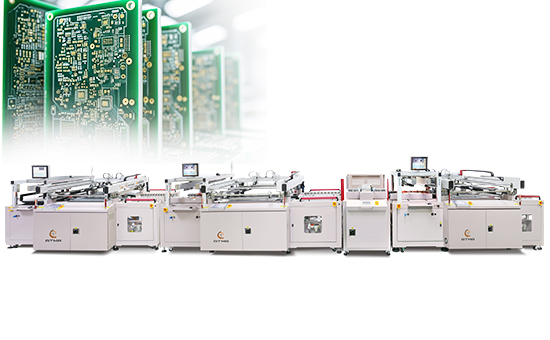

SPS Front Pick-up Feeder (max. sheet 550X750mm)

SPS FVF FP57

FP Front Pick-up Feeder, is specialized in handling thinner sheets, used to work with an SPS High Speed Fully Automatic Cylinder Screen Printing Machine, run synchronously linked, highlights German SPS’s lineage classic advantages: smooth run by gentle sheet handling, printing accuracy, operation convenience and comfort, maintains medium high yield.

- Linked and sync-run with an SPS high-speed Cylinder Screen Printing Machine, feeds piled up sheet stock piece by piece into Printing Machine for printing.

- Suitable for paper, plastic, etc. flexible, usual to thinner sheets, rectangular sheet substrates, such as:

- Graphic Printing: posters, packaging boxes/ wraps, book covers, stickers, greeting cards, labels/tags, braille, scratch-offs…

- Industrial Printing: transfers/decals (textile, ceramic, bikes, sports devices…), automotive/appliance dashboards/panels (IMD/FIM...), security cards (credit, ID…), membrane switches…

- Circuit Printing: flexible circuits (circuits, conductive contacts…), electronic labels, sensors…

- Opto-electronic Printing: electro-luminescence (electrode, emission layer…), flexible cover-lenses…

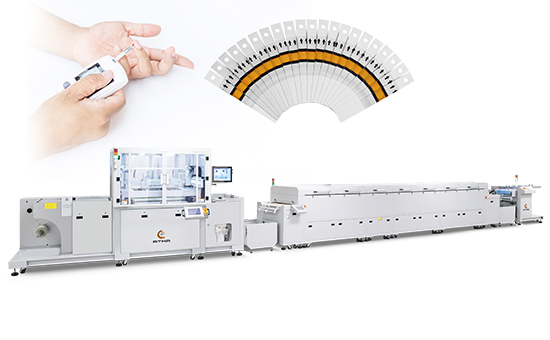

- Bio-medical Printing: health-care test strips (blood sugar…).

- Green Energy Printing: thin film batteries… - Max. speed 2800 cycle/h (max. sheet 550x750mm).

Features

- 3-side portal design, allows operator access for pile setup.

- Pile guides with scale.

- Pile height sensor with automatic feed-in control.

- Unique dynamic variable vacuum pick-up head, air-blow + poke multiple sheet-separation system, suction cups’/air-blow nozzles’strength/positions/angle are delicately adjustable, to handle Varying thickness/rigidity of sheet materials, for sure effect..

- Ultrasonic double-sheet detection.

- Unique servo-driven varying speed single-sheet forwarding, and gentle reaching position, to sheet characteristics.

- Control linked with Printing Machine after, with further control switches nearby operation position, convenient for setup

Options

- Sheet cleaning roller device, ensures print quality.

- Anti-static device, eliminates static charge on plastic sheets, for smooth run.

- With other options, corresponding to process requirements.

Specification

- maxsheet size: 550x750mm (22”x30”) ~ 250x300mm (10”x12”) ; thickness: 0.075~0.8mm (0.003”~0.03”)

- machine dimension(standard machine):1380x1680x1220mm (3’ 7” x 5’ 6” x 4’)

Other models in same series but different size:

XP screen tilt lift typeSPS FVF FP 71 [maxsheet size: 750x1060mm (29”x41”)

thickness:0.075~0.8mm (0.003”~0.03”)]

Other models for same application but in different type:

EP Rear Pick-up FeederSPS FVR EP 57 [maxsheet size: 550x750mm (22”x30”)]

thickness: 0.2~0.8mm (0.008”~0.03”)]

SPS FVR EP 71 [maxsheet size: 750x1060mm (29”x41”)

thickness: 0.2~0.8mm (0.008”~0.03”)]

- Related Products

SPS Front Pick-up Feeder (max. sheet 550X750mm) | ATMA

Use our SPS Front Pick-up Feeder (max. sheet 550X750mm) to compare machine types by application—sheet, cylinder press, or roll-to-roll—so you can shortlist the right format for your production.

ATMA has manufactured screen printing equipment since 1979, and we can help you align the screen printer with feeders, dryers, coaters, and ink mixing modules.

Share your substrate, print size, and throughput target—ATMA will recommend a screen printer configuration and the next steps for evaluation.