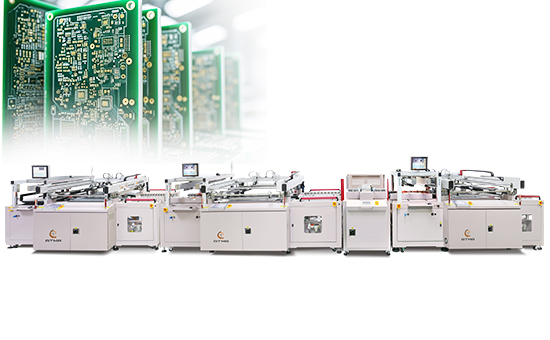

SPS Fully Automatic Twin-flow STOP Cylinder Screen Printing Machine (max. sheet: twin-flow 520X500mm, single-flow 750X1060mm, 4-post screen lift, flagship model)

SPS VTS SL71/t

also called Cylinder Screen Printing Press, Cylinder Press

Based on the SL71 4-post screen lift type primeline luxury class flagship model, the SL71/t is further transformed to an unique twin/single-flow compatible model (/t), offers double yield and adaptability to diversified print jobs. Highlights the superior German SPS lineage classic: the “Original SPS STOP Cylinder Principle” in advantages: highest run speed, printing quality, operator convenience and comfort, ever seen in the market)

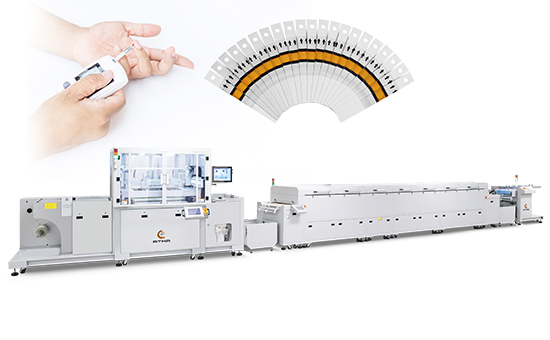

- Linked with a Feeder (twin-flow type) ahead, and Dryer lined up after (various types, up to drying principle of ink printed), and Stacker (twin-flow type) further, as a complete automatic feeding – printing – drying – stacking process line.

- Suitable for paper, plastic, etc. flexible sheet substrates, in [half size small sheet twin-flow, single-flow taking any side of the small sheet twin-flow, full size large sheet single-flow] selectable versatile operation modes, to be printed graphic images, special effects (varnish, relief, particle, gloss…), such as:

- Graphic Printing: posters, packaging boxes/ wraps, book covers, stickers, greeting cards, labels/tags, braille, scratch-offs… - Must work with an SPS Feeder (twin-flow type) ahead, 2 types for choice: Rear Pick-up type SPS FVR EP71/t, Front Pick-up type SPS FVF FP71/t, depending on substrate thickness.

- Max. speed 4000 cycle/h x1 = 4000 p/h, x2 = 8000 p/h (with EP71/t Twin-flow Rear Pick-up Feeder); Or 2500 cycle/h x1 = 2500 p/h, x2 = 5000 p/h (with FP71/t Twin-flow Front Pick-up Feeder). (max. sheet: single-flow 750x1060mm / 520x500mm x1; twin-flow 520x500mm x2).

Features

- Auto-lubricated balanced drive system, performs constant stability and accuracy in high/low speed and long/short run (feed-in – registration – printing – delivery).

- Finely produced cylinder integrated sequenced vacuum/blowback and grippers, for controlled printing stability hence even ink deposit.

- Front stops + push/pull vacuum side guides + optical sensors sheet registration system, working with Non-Print / Auto-Stop protective controls, avoids sheet waste.

- Screen side push-in loading + guides + centralized 3-point screen adjustments, for convenient and comfortable setup.

- Pneumatic screen tilting, working with Auto-Stop programs, controls ink parking on screen – anti-drip, convenient cleaning.

- PEH multiple controlled squeegee pressure + electronic sequence/stroke system, squeegee is automatically controlled securing print quality.

- Motorized + electronic pressure controlled + micrometer indicated squeegee set-down system, automates fast setting at uniform accuracy.

- Squeegee bridge pneumatic tilting + drip pan, for fast clearing squeegee off screen and convenient change.

- Delivery belt in varying speed (synced to up/down-stream machines) + fold-down exit part (convenient access for service).

- High-level master-control PLC + attentive control programs + package movements, for convenient operation and error-proof.

- Eye-level high-erected operator interface + multiple nearby control panels, for convenient and comfortable operations.

- Error diagnose/indication and history record, on-line remote diagnose.

Options

- Anti-static device, eliminates static charge on plastic sheets. for smooth run.

- Print length correction system, corrects screen mesh deviation.

- C05 squeegee system, ensures printing quality, fast and lightweight in change.

- Synchroline control, for in-line control and automatic speed syncing.

- With other options, corresponding to process requirements.

Specification

- for sheet size: twin-flow 750x500(x2)mm [29”x20”(x2)] ~ 280x140(x2)mm [11”x5½”(x2)] ; thickness: 0.075~0.8mm (0.003”~0.03”)

- for sheet size: single-flow 750x1060mm (29”x41”) ~ 280x420mm (11”x14”) ; thickness: 0.075~0.8mm (0.003”~0.03”)

- screen size(fixed, choose one): 1140x1280mm (45”x50”), 1250x1320mm (49”x52”)

- machine dimension(standard machine): 2690x2160x1930mm (8’ 10” x 7’ 1” x 6’ 4”)

Other models for same application, but in different type: XP57/t screen tilt type

SPS VTS XP57/t [maxsheet:twin-flow 550x267(x2)mm [22”x10.5”(x2)]

single-flow 550x750mm (22”x30”)]

- Related Products

SPS Fully Automatic Twin-flow STOP Cylinder Screen Printing Machine (max. sheet: twin-flow 550X267mm, single-flow 550X750mm, tilt screen lift, primeline luxury class)

SPS VTS XP57/t

Based on the XP57/p tilt screen lift type primeline luxury class, the XP57/t is further transformed to an unique twin/single-flow compatible model (/t), offers double yield and adaptability to diversified...

Details

SPS Fully Automatic Twin-flow STOP Cylinder Screen Printing Machine (max. sheet: twin-flow 520X500mm, single-flow 750X1060mm, 4-post screen lift, flagship model) | ATMA

Use our SPS Fully Automatic Twin-flow STOP Cylinder Screen Printing Machine (max. sheet: twin-flow 520X500mm, single-flow 750X1060mm, 4-post screen lift, flagship model) to compare machine types by application—sheet, cylinder press, or roll-to-roll—so you can shortlist the right format for your production.

ATMA has manufactured screen printing equipment since 1979, and we can help you align the screen printer with feeders, dryers, coaters, and ink mixing modules.

Share your substrate, print size, and throughput target—ATMA will recommend a screen printer configuration and the next steps for evaluation.