Applications

Screen Printing Applications

Welcome to browse our screen-printing machinery product portfolio, owing to its characteristics as highly suitable for Substrates and Inks, hence can be widely applied in various processes and wide diversities. Our screen-printing equipment is therefore designed / developed coping with such processes in diversities.

To ease your searching, identifying, thus quickly finding corresponding models possibly meet your needs, our product is classified by diversification of several major application segments (as below), guiding you to click in for understanding.

Further, you might have found our products are in two brand series: ATMA and SPS, they are different in printing run principle and automation degree:

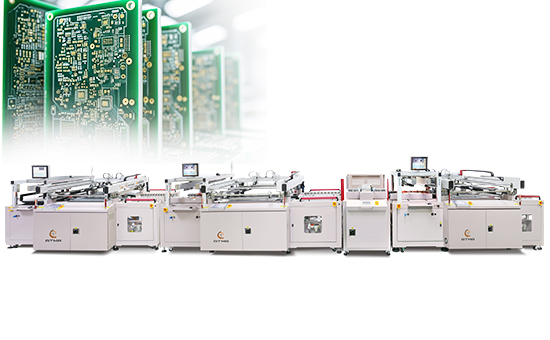

- ATMA : for substrates in sheet/panel forms [*], adopts “flat-bed(table)” as substrate support base, added various modularly designed Printing Section (consists of stationary Screen Section and moving Printing Head), different degreed substrate in/out conveyance mechanism, and pre-print/post-print affiliated function sections for serial processes; Flat-bed type has the characteristics of being easy to operate and control, and accurate in print, suitable for industrial processes requiring accuracy rather than high productivity; [ * partial models may handle stereo molded substrates with printable flat or cylindrical surface, usually work with jig/holder: jig on table, rotating holder for cylindrical substrates; (see Industrial Printing) Recently also developed available models in Roll-to-roll work-flow principle for flexible substrates in roll form; (see Fully Automatic Roll-to-roll Screen Printing Line) ]

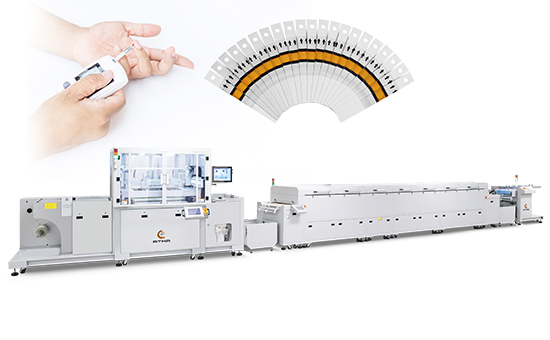

- SPS : for substrates in flexible sheet form, adopts “rotating cylinder” as substrate support base, added specific Printing Section (consists of moving Screen Section syncing to cylinder, and stationary Printing Head), automatic substrate infeed – positioning – printing – delivery conveyance mechanism, and pre-print feeding, post-print drying/stacking…in-line equipment for fully automatic serial processes; Cylinder type has the characteristics of being fully automated, in high run speed(=high productivity), suitable for processes requiring high automation and high productivity; (see SPS Fully Automatic Screen Printing Line) ]

Find Screen Printing Equipment by Category

Use categories to locate screen printing equipment that matches your material, automation goals and workflow.

ATMA has supported industrial printing lines for 40+ years, helping teams choose compatible machines and accessories.

Start with a category, shortlist options, and contact ATMA for a practical fit-check before you finalize.