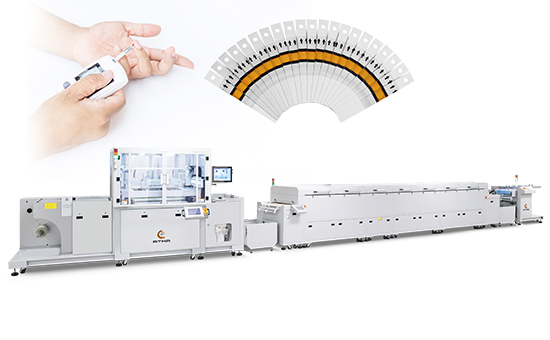

Pneumatic Mini Flat Screen Printer

TY-500FAT

Flat Screen Printer, Pneumatic Type Screen Printer, Mini Flat Screen Printer

Initially invented pneumatic type flat screen printer, suitable for printing various industrial products like Nameplate and Cards, all kind of flat sheet / plate / panel of material Acrylic, Plastic, Plastic, Metal, etc.

Corresponding to diverse production efficiency, versatile feature like three-point screen micro-adjustment for easy registration, table with vacuum function, CPU control, etcwhich is the best choice of small size screen printer

Features

- Screen vertical up down to prevent ink flow to lateral side.

- Three-point screen micro adjustment, table can be adjusted in direction front / back / right / leftward to facilitate multi-layer printing.

- Optimal closed chamber buffer device to eliminate rapidly vibration phenomenon upon collision.

- Safety insertion pin facilitates to exchange squeegee / flood coater / screen and cleaning residue ink.

- Design of the retractable print head carriage ensures centric position for printing.

- CPU control, selectable various printing cycle mode corresponding to diverse printing requirement.

- E-stop pressing plate is used to protect operator safety and decrease defective rate.

Specification

| Model | TY-500FAT |

|---|---|

| Substrate Thickness | 0.1〜80mm |

| Max Productivity | 820 P/H |

| Max Printing Area | 300x460mm |

| Max Frame O/D Size | 450x650mm |

| Table Size | 400x600mm |

| Vacuum Hole Diameter | ϕ 1.5mm |

| Power Consumption | 0.28KW |

| Air Exhaustion | 165.3L/min |

| Machine Weight | 190kg |

| Machine Dimension | 820x630x1610mm |

Other models in the same series but different sizes:

TY-500FABT (max printing area Flat 300x460mm Curve Φ50-Φ145mm) AT-60FA (max printing area 405x600mm)- Related Products

Pneumatic Mini Flat Screen Printer | ATMA

Use our Pneumatic Mini Flat Screen Printer to compare machine types by application—sheet, cylinder press, or roll-to-roll—so you can shortlist the right format for your production.

ATMA has manufactured screen printing equipment since 1979, and we can help you align the screen printer with feeders, dryers, coaters, and ink mixing modules.

Share your substrate, print size, and throughput target—ATMA will recommend a screen printer configuration and the next steps for evaluation.