China (Shenzhen) International Screen Printing and Digital Printing Technology Fair (2020 CSGIA)

CSGIA is the renowned Chinese professional screen printing trade fair, attracting visitors from high precision fields such as textile heat transfer, stained paper, IMD, etc. It will be held at Shenzhen exhibition hall in year 2020, nearby Shenzhen Baoan Airport convenient transportation.

ATMA is leading brand name for screen printing equipment over all the world, high precision, automatic screen printer & accessories will be displayed at CSGIA. Guangdong is an important base of printing industry, replying on China’s policy dividend to promote vigorously construction of the Guangdong-HongKong-Macao Great Bay Area, the scale and professionalism of trade fair CSGIA 2020 will inevitably expand and strengthen.

Date : 2020/10/28 ~ 10/30

Place : Shenzhen World Exhibition & Convention Center (new building, nearby Shenzhen Baoan Airport)

Booth No : H01-10

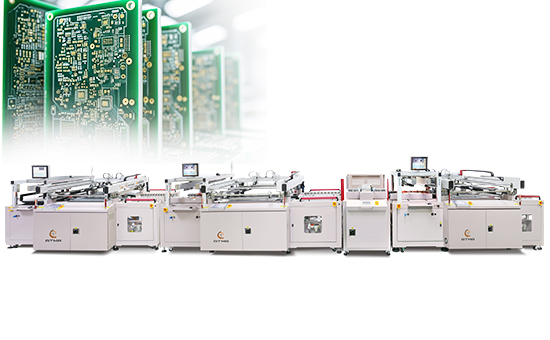

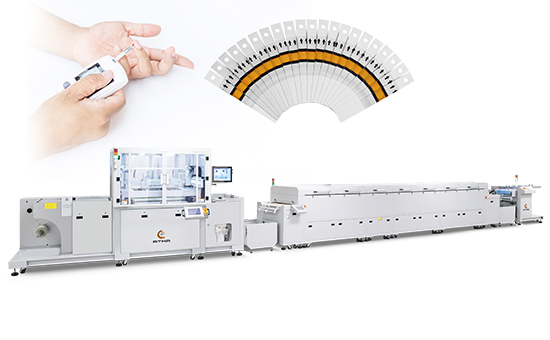

- Machines on ATMA booth

China (Shenzhen) International Screen Printing and Digital Printing Technology Fair (2020 CSGIA) | Meet ATMA at Events & Exhibitions

Meet ATMA—an established screen printing equipment manufacturer—so you can evaluate suppliers with clear product scope and support expectations.

Since 1979, ATMA has manufactured screen printers and related modules, including feeders, air dryers, coating machines, and ink mixers for production lines.

Share your application and project goals—ATMA will suggest suitable screen printing equipment options and the next steps to move forward.