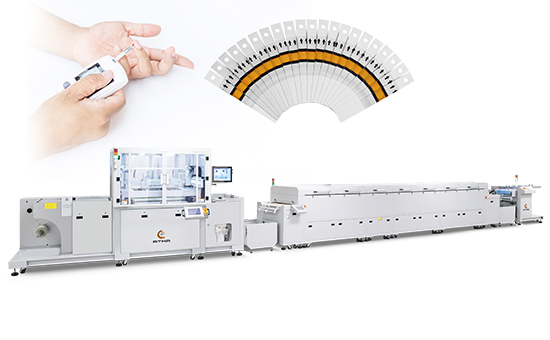

Automatic Automotive Front / Back Windshield Screen Printer

ATMATIC GS1220

Glass Screen Printer, Architecture Glass Screen Printer, Automotive Glass Screen Printer, Photovoltaic Glass Screen Printer

Suitable for screen printing on large format glass, such as door for refrigerator, automotive dormer glass, automotive front / back windshield glass, photovoltaic glass and so on.

Features

- Connected Frame Structure : screen frame holder is used connected frame design, robust structure, suitable for heavy pressure with large area printing.

- Conveyor Belt : conveyor belt adopts high friction NOK timing belt special for glass, conveyor belt up down is driven by air cylinder.

- Clapper Registration : enable to make associated or independent moving, suitable for symmetrical or asymmetrical glass alignment, registration pins is used PEEK material

- Quick Adjustment : brand new design the printing head carriage, integrated various adjustment structure like squeegee / flood coater angle / depth /printing pressure, etc

- Height Micro Adjustment Knob : frame holder at four corners has distinctly height micro adjustment device, which enables to adjust individually single side of frame height leveling.

- Operational Identification : equipped with LED three color lamp explicit indicating operational status, convenience for operator or service staff identifies

- Safety Protection : equipped with safety bar and E-stop switch, comprehensive safety protection.

Specification

| Model | ATMATIC_GS1220 |

|---|---|

| Substrate thickness | 1.4〜12mm |

| Productivity | 240 P/H |

| Max printing area | 1200x2000mm |

| Min printing area | 400x600mm |

| Max frame O/D size | 1800x2800mm |

| Min frame O/D size | 120x1800mm |

| Vacuum holes size | ϕ2.0mm |

| Machine weight | 1,800kg |

| Machine dimension | 3580x2300x1600mm |

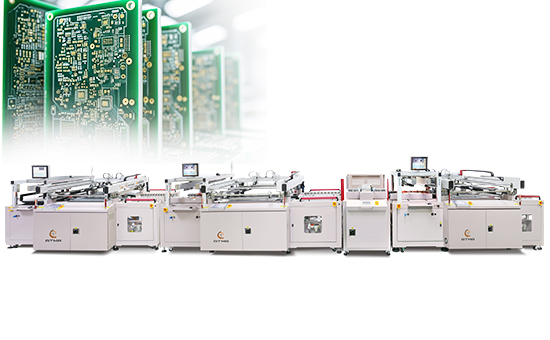

Other models in the same series but different sizes:

ATMATIC GS1225 (max printing area 1200x2500mm)ATMATIC GS1322/W (max printing area 1300x2200mm)

- Related Products

Automatic Automotive Front / Back Windshield Screen Printer | ATMA

Use our Automatic Automotive Front / Back Windshield Screen Printer to compare machine types by application—sheet, cylinder press, or roll-to-roll—so you can shortlist the right format for your production.

ATMA has manufactured screen printing equipment since 1979, and we can help you align the screen printer with feeders, dryers, coaters, and ink mixing modules.

Share your substrate, print size, and throughput target—ATMA will recommend a screen printer configuration and the next steps for evaluation.