TPCA Show 2020

In recent years, the growth rate of the global PCB industry has become stabilized. In terms of product types, the global PCB industry is moving closer to high precision, high density, and high reliability within constantly reduce volume and improve performance to adapt the downstream electronic equipment industries development need. This means company will spend more cost in technology and research development. In terms of production efficiency, global labor costs are rising, competition is increasingly fierce. Therefore increasing efficiency and reduce the cost has become the major issue for all the PCB industries. Smart production and fully automation will be a direction to support PCB industry move into the next level.

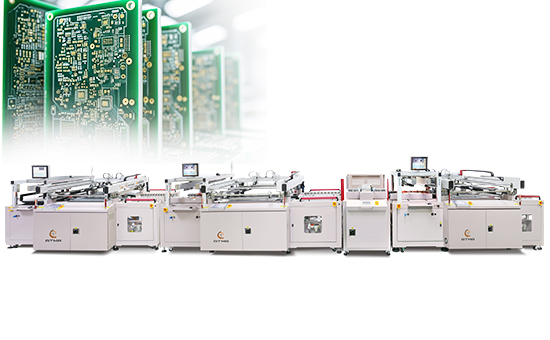

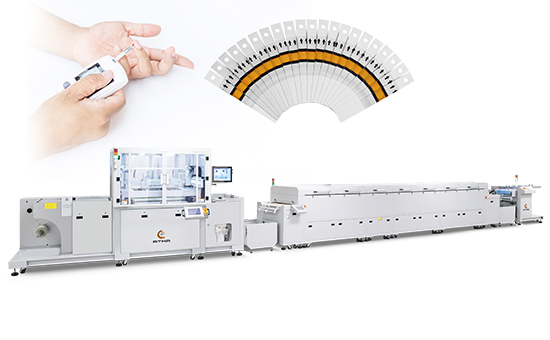

ATMA keeping the pace of PCB development, from the original semi-automatic to advance fully-automatic machine development, now, we can provide fully production line to match the customer and the market requirement included all the screen printing production such as test, plug hole, solder mask and carbon ink. If you looking for PCB screen production on PCB process, ATMA machine can fully satisfy your needs. New development of fully automatic double side injek printing and thick and thin circuit board screen printing machine very soon to make first debut on the market. We are looking forward to see you and welcome you to visit our booth in that day.

Date : 2020/12/21 ~ 12/23

Place : Taipei Nangang Exhibition Center

Booth No : M0720

- Machines on ATMA booth

TPCA Show 2020 | Meet ATMA at Events & Exhibitions

Meet ATMA—an established screen printing equipment manufacturer—so you can evaluate suppliers with clear product scope and support expectations.

Since 1979, ATMA has manufactured screen printers and related modules, including feeders, air dryers, coating machines, and ink mixers for production lines.

Share your application and project goals—ATMA will suggest suitable screen printing equipment options and the next steps to move forward.