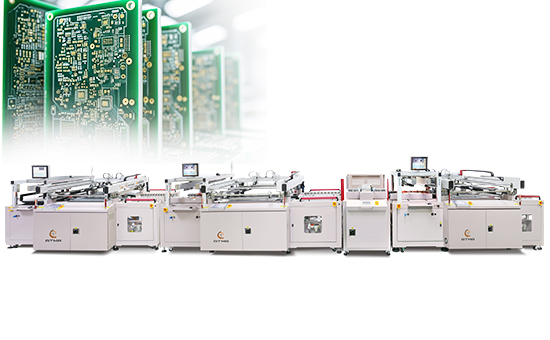

Twin Table Wet-film Plug-via Screen Printer

ATMAOE EW68TT

Wet-film Plug-via Screen Printer, Solder Mask Screen Printer, Twin Table Plug-via Screen Printer

Dedicated to process screen printing photoimageable resistance solder mask wet film plug / non-plug-via on PCB.

Initiative double squeegee bidirectional printing + bidirectional peel-off + bidirectional table displacement and so on patented function, double machine operating, drying after both sides to be printed, precise control (circuits corner crack may not be left out printing), (bidirectional printing ink misaligned / precise), (auto cleaning residue ink beneath screen mesh), ( plug-via holes satiation, don’t bump after drying) and so on perfect printing effect, significantly increase printing speed and yield rate, leading the trend of PCB production mainstream

Features

- Double Squeegee / Double Peel-off : double machine cooperate operation or single machine accomplishes both sides printing, drying once to raise production efficiency.

- Table Displacement : enable to follow printing stroke to move at X/Y axis direction, correct the misaligned bidirectional printing to acquire ink transfer consistence or cleaning residue ink on mesh while printingMovement distance can be fine adjusted

- One Button Locking : when fine adjusting upper / lower table, just press a button to unlock / lock to raise speed of screen positioning

- Angular Adjustment : inner / external tilt angle adjustment to facilitate outstanding character of accuracy and strength.

- Centric Peel-off Device : restrict stroke of screen off-contact while printing to achieve plug-via hole ink transfer consistence

- Blockade Shelter : non-plug-via portion where makes blockade shelter, plug-via portion is printed directly by opened mesh, one time process to achieve two effects.

Specification

| Model | ATMAOE_EW68TT |

|---|---|

| Substrate Thickness | 0.1〜10 mm |

| Max Productivity | Approximately120〜180 P/H (depended on the aspect ratio, ink viscosity and squeegee speed to cause difference) |

| Max Printing Area | 690(D) x 710(W)mm(H-type squeegee at angle 20°) 610(D) x 710(W)mm(H-type squeegee at angle 30°) |

| Table Size | 1000x950mm |

| Max Frame O/D Size | 1200x1200mm(equipped with screen displacement device) 1300x1300mm(without screen displacement device) |

| Print Head Skew Angle | ±5° |

| Double Squeegee Angle | Inner / external angle 30° |

| Peel-off Height | 0〜25 mm |

| Air Exhaust | 25 L/min (including screen displacemen) |

| Power Consumption | 4.3kw (optional vacuum 5.8kw) |

| Machine Weight | 1300kg |

| Machine Dimension | 1800x2810x1400mm |

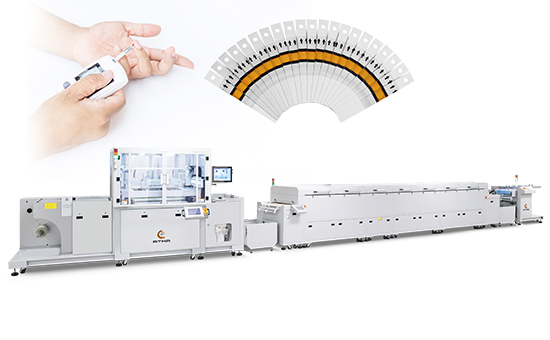

- Related Products

Twin Table Wet-film Plug-via Screen Printer | ATMA

Use our Twin Table Wet-film Plug-via Screen Printer to compare machine types by application—sheet, cylinder press, or roll-to-roll—so you can shortlist the right format for your production.

ATMA has manufactured screen printing equipment since 1979, and we can help you align the screen printer with feeders, dryers, coaters, and ink mixing modules.

Share your substrate, print size, and throughput target—ATMA will recommend a screen printer configuration and the next steps for evaluation.