Transfer Paper Screen Printer

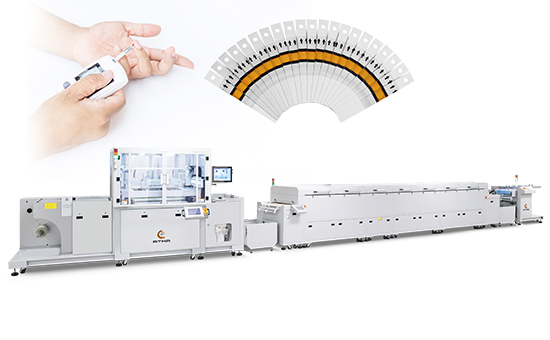

Transfer paper screen printer is used to print heat / water transfer for textiles and art crafts.

ATMA transfer screen printer provides a wide range of screen printing solution to achieve production speed, precision and stability, such as the affordable fully automatic cylinder press, 3/4 automatic and 1/2 automatic flatbed screen printer to fulfill different production scale level to fulfill versatile multi-color printing in various sizes.

The fully automatic SPS cylinder press is configured with various features to achieve high speed and precision printing, its production capacity 4000 pph and is suitable for plastic and paper transfer materials. Like the feature of equalizing PEH system to control squeegee / flood coater pressure to obtain evenness ink layer in high speed printing. Side lay registration to obtain accuracy +/- 0.04 mm can print with perfect registration across processes onto offset printed sheets. Adding, print elongation control compensates the image “fit” difference which is caused the mesh stretching of screen printing. All those features are dedicated to achieve quality and efficient massive production to lower labor cost.

Alternative, the affordable 1/2 and 3/4 automatic flatbed screen printing machine is suitable for diverse small volume production, such machine is configured with flexibility and simple operation, quick setup and the printing parameters recipe can be preset on HMI, unskilled operator can handle quality printing. Also, ATMA provides the advanced solution of flatbed screen printer with CCD cameras registration to attain high precision printing and quality fine line printing.

ATMA screen printing solution is suitable for printing on all kind material as PC, PE PET, PVT sticker or decal with excellent adhesion and colorful graphic image. Applicable models handle printing area in range 200x250 ~ 1000x1400 mm.

Applicable models

(1)1/2 Automatic Model :

AT-60FA

Pneumatic Flat Screen Printer

AT-80P

Electric Flat Screen Printer

AT-70PD

Digital Electric Flat Screen Printer

AT-68C

High-speed Clamshell Screen Printer

ATMAOE MF66

Automatic CCD Registering Screen Printer

(2) 3/4 Automatic Model

AT-80PP/G

Electric Sliding Table Screen Printer with Gripper Take-off

ATMACE 710/G(6)

Four-post Screen Printer with Gripper Take-off

(3) Fully Automatic Model :

ATMAOE MF66-F

Fully Automatic CCD Registering Screen Printer

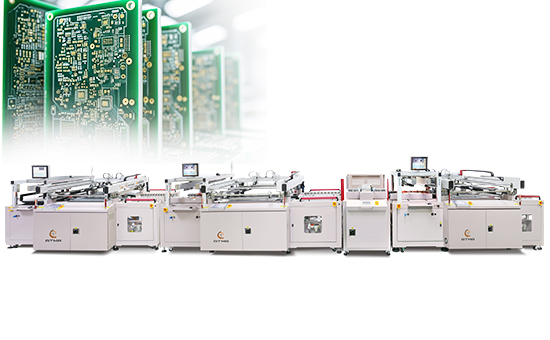

(4) Fully Automatic Printing Line :

Integrated feeding-printing-drying-collecting in one complete production line

SPS High speed Fully Automatic Cylinder Screen Printer ( flexible substrate, thickness 0.08~0.8 mm) 4-post screen lift type, luxury class:

SPS VTS SL71

(max substrate size 750x1060mm)

tilt screen lift type, luxury primeline class :

SPS VTS XP57/p

(max substrate size 550x750mm)

tilt screen lift type, classic class :

SPS VTS XP71

(max substrate size 750x1060mm)

Collocated SPS Conveyor Dryer series (configured depending on ink drying condition) Hot / Cold Jet Air + UV Combination Conveyor Dryer :

SPS CBS 71

(working width 1100mm, 90ºC)

SPS CBS 57

(working width 800mm, 90ºC)

Collocated SPS Automatic Sheet Stacker series

SPS STK AS71

(max substrate size 750x1060mm)

SPS STK AS57

(max substrate size 550x750mm)

Collocated SPS Reject Sheet Selector series (printed-pass / unprinted-bypass)

SPS RSS RS71

(max substrate size 750x1060mm)

SPS RSS RS57

(max substrate size 550x750mm)

SPS Fully Automatic STOP Cylinder Screen Printing Machine (max. sheet 550X750mm, tilt screen lift, primeline luxury class)

SPS VTS XP57/p

Based on the XP tilt screen lift type’s superior German SPS lineage classic: the “Original SPS STOP Cylinder Principle” (advantages: highest run speed, printing quality, operator convenience and comfort,...

DetailsSPS Fully Automatic STOP Cylinder Screen Printing Machine max. sheet 750X1060mm, tilt screen lift, classic economy class)

SPS VTS XP71

XP tilt screen lift type is German SPS’s lineage classic series: with the superior “Original SPS STOP Cylinder Principle”, demonstrates the highest run speed, printing accuracy, operation convenience...

DetailsSPS Fully Automatic STOP Cylinder Screen PRINTING MACHINE (max. sheet 750X1060mm, 4-post screen lift, flagship model)

SPS VTS SL71

SL 4-post screen lift type, as SPS’s flagship model, is based on the superior German lineage classic: the “Original SPS STOP Cylinder Principle” (advantages: highest run speed, printing quality,...

DetailsTransfer Paper Screen Printer | ATMA

Browse our screen printer catalog to compare models by printing format, automation level, and line compatibility—then narrow to the best-fit options.

Since 1979, ATMA has focused on screen printing equipment, supporting buyers in selecting a screen printer and matching accessories like feeders and air dryers.

Tell us your material and output goals—ATMA will propose a screen printer setup and a clear shortlist to move forward.