2022 Touch Taiwan International Display Exhibition

Touch Taiwan is one of the most influential electronics industry exhibition leading brands on the world. Meanwhile, it is also an exchange event of Taiwan high-tech industry chain, and is completely integrated Display, Optoelectronic, Semiconductor, Smart Manufacturing, Electronic Equipment, Industrial Material, Commercial Display, Digital Signage, Smart City, Industrial Computer, Wearable Display, Virtual Reality, Automotive Electronics, etc. Purpose for this event establishes a platform to integrate transboundary industry for an opportunity of blue ocean business.

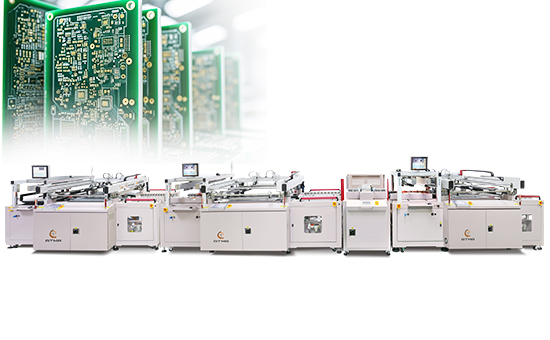

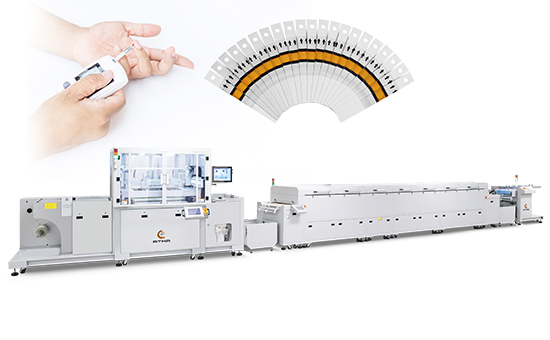

ATMA provides fully automatic and semi-automatic equipment for the screen printing process of optoelectronic industry, and is equipped with high accuracy visual registration function to fulfill the needs of high end products, it takes into account the optimal benefits of production capacity and yield rate.

The actual machine and video of equipment will be displayed at show booth, you are welcome to visit ATMA show booth, presentation will be provided by our Sales Rep upon request.

Show machine : ATMAOE MF44 Automatic CCD Registering Screen Printer

Applicable for PET, PVC film, flexible printed circuit (FPC), Touch Panel, Optical Acrylic and so on.

Product Advantage

- Automatic CCD registering : overcome the deviation of material expansion and contraction as well as manual alignment.

- Adapt servo motor control : precise positioning and stable operation.

- Digital control HMI setting : fulfill the need of SOP process.

- Precise machining : joint surface is machined precisely to ensure assembly parallelism.

Date : April 27th ~ 29th, 2022

Place : Taipei Nangang Exhibition Center, Hall 1, 4 Floor

Booth No : N zone 114

- Machines on ATMA booth

2022 Touch Taiwan International Display Exhibition | Meet ATMA at Events & Exhibitions

Meet ATMA—an established screen printing equipment manufacturer—so you can evaluate suppliers with clear product scope and support expectations.

Since 1979, ATMA has manufactured screen printers and related modules, including feeders, air dryers, coating machines, and ink mixers for production lines.

Share your application and project goals—ATMA will suggest suitable screen printing equipment options and the next steps to move forward.