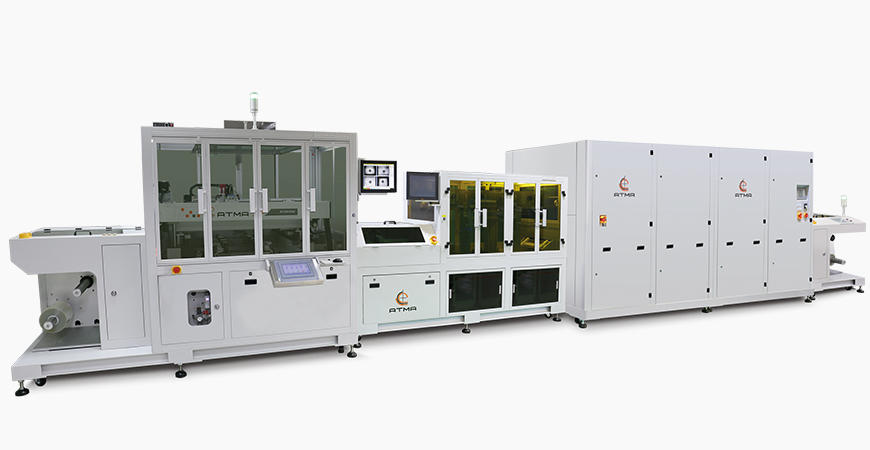

Roll-to-Roll Screen Printing Line

Multi-function automatic Roll-to-Roll production line for all flexible rolled material,...

Read MoreFully Automatic Roll-to-Roll Screen Printer, Fully Automatic RtR Screen Printer, Fully Automatic Reel-to-Reel Screen Printer

Among next generation of sunrise industries, FPC (Flexible Electronics) technology is being developed rapidly, flexible electronics is generally known technology, which is configured components onto thin film or metal foil or flexible substrateApplication of flexible electronic technology is widely used currently, except for the earlier development and mature technology of FPC industry, Flexible Display, E-paper, Thin Film Solar Cell, RFID and so on is application scope of flexible electronics, great potential development in futureCombined with Roll-to-Roll continual processing to produce flexible electronic products, also achieves advantage of production efficiency and cost down.

R2R continual production equipment and transmission technology, it will be the most futuristic world trend of industry, such technology will cause tremendous innovation of industry from material, equipment, processing, product design, driven circuits etc

| Model | AT_RR2350-C (Unwinding Machine) |

|---|---|

| Feed-in Mode | Vacuum roller winding |

| Transmission Mode | Servo power winding |

| Proceed along edge Mode | Structural EPC |

| Proceed along edge Margin | ±10mm |

| Tension Control Mode | Vertical type, servo control |

| Unwinding Tension | 0.5〜3.0kgf |

| Unwinding Speed | 10〜100mm/sec |

| Cutting / Lamination Device | Attachment |

| CCD Camera | 4 pcs |

| FOV scope | 15x20mm |

| Image Detection Mode | Detect up / down registration mark simultaneously |

| Camera detection scope | X=±75~±250mm Y=±100~±170mm |

| Operation Interface | HMI (parameter setting) |

| Enclosure Mode | Feed-in Section : upper enclosure Printing Section : full enclosure |

| Power Source | 3∮,220/380V,50/60Hz |

| Machine Dimension | 3525x1725x2350mm |

| Machine Weight | 2,220kgs |

| Model | AT_RI3250 (Inspection) |

|---|---|

| Quality Inspection | Manual moving CCD inspection + monitor display (12.1 inch) |

| Inspection CCD Camera Number | 1 pc (colored camera) |

| Camera FOV | 12.5x17 mm |

| Inspection Area | 340x500 mm |

| CCD Height | 91mm |

| Conveyor Speed | 10~100mm/sec (可調) |

| Conveyor Delivery | Vacuum roller conveyor, servo motor driven |

| Vacuum Mode | Vacuum ring blower |

| Cutting / Lamination Device | Yes |

| Air floating Inspection Platform | Yes |

| Material Connecting Structure | Yes (3” Air Shaft) |

| Equipment Exterior Enclosure | Lift protective cover |

| Power Source | 3∮,220/380V,50/60Hz |

| Machine Dimension | 1475×870×1840mm |

| Machine Weight | 700 kgs |

| Model | AT_RB3250 Standstill Machine |

|---|---|

| Conveyor Speed | 10~100mm/sec (adjustable) |

| Conveyor Mode | Vacuum conveyor roller, servo driven |

| Vacuum Roller Height | 1780+60 mm |

| Vacuum Roller Group | 6 sets (induction motor driven) |

| Vacuum Mode | Vacuum ring blower |

| Equipment Exterior Enclosure | Enclosure protection |

| Power Source | 3∮,220/380V,50/60Hz |

| Machine Dimension | 3495×955×2410mm |

| Machine Weight | 1150 kgs |

| Model | AT_RIO4032 Dryer |

|---|---|

| Conveyor Delivery | Vacuum roller |

| Effective Conveyor Width | 250、300、320、340mm |

| Transmission Mode | Vacuum roller transmission |

| Conveyor Height | 1750+60mm |

| Conveyor Speed | 0.5~6 M/min |

| Heating Mode | IR + Hot air circulation |

| Heating Section | 4 sections |

| Conveyor Length | Total 16M |

| Ventilation | Air blower |

| Ventilative Direction | from up to down |

| Material | Thermal isolation inner layer adopted SUS 430 Thermal isolation external layer adopted SS41 lacquer |

| Warm Up System | Hot air +IR |

| Temperature Control System | Adopt SCR control IR SSR control hot air circulation |

| Temperature Control System | Hot air circulation |

| Temperature Range | Room temperature +20~200℃ |

| Circulation System | 10.5 inch fan circulation |

| Average Temperature | Setting temperature within ±3% |

| Operation Interface | Proface 7 inch touch screen, setting parameters |

| General Setting | Heat extraction 16CMM (mechanical valve adjustable flow rate) |

| Protection Device |

|

| Power Source | 3∮,220/380V,50/60Hz |

| Machine Dimension L×W×H | 4300×1500×2100mm (heating section length : 3760mm) |

| Machine Weight | 3,270 kgs |

| Model | AT_RW3250 Winding Machine |

| Winding mode | 90° vacuum roller conveyor (servo motor driven) |

| Winding Speed | 10~100 mm/sec |

| Vacuum Mode | Ring Blower |

| Proceed along edge Mode | Corrector + Structural EPC±10mm |

| Tension Control Mode | Loadcell + Servo control |

| Winding Tension | 0.5~3 kgf |

| Operation Interface | Proface 7 inch HMI, parameter setting |

| Equipment Exterior Enclosure Mode | Lift protective cover |

| Power Source | 3∮,220/380V,50/60Hz |

| Machine Dimension | 1250×1195×1390mm |

| Machine Weight | 650 kgs |

Multi-function automatic Roll-to-Roll production line for all flexible rolled material,...

Read More

Breakthrough conventional process mode, three times printing with three times drying,...

Read More

Screen printing speed attains highest 4000 cycles per hour within industry, under high...

Read More